Diecasting: The Backbone of Precision Manufacturing

Diecasting: The Backbone of Precision Manufacturing

Blog Article

Diecasting is a specialized manufacturing method that turns melts of metal into precisely-defined components through the use of high-pressure molds. The technique is now indispensable in a variety of industries, such as electronics, aerospace, automobiles as well as consumer products, due to its ability to produce complex shapes with exceptional reliability and accuracy. In combining the principles of metals with modern engineering, diecasting offers unmatched effectiveness and precision. This makes it a fundamental element for modern manufacturing. This article explores the complex world of diecasting by looking at its procedure, advantages and potential applications.

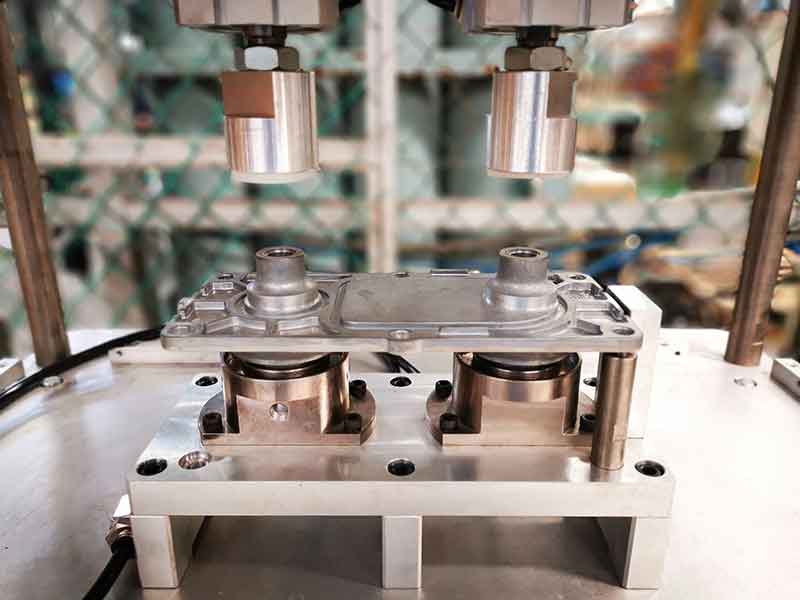

The process of diecasting starts with the creation of top-quality steel molds, known as dies. These molds are created to withstand the rigors of pressure as well as the high temperatures produced by molten steel. Dies are carefully designed to take in intricate details and keep tight tolerances ensuring that each cast part has the right specifications. When casting is performed, metallic components like aluminum magnesium, zinc, as well as copper are first melted before being introduced into the die cavity with high pressures. This quick injection, and its subsequent cooling result in parts which have excellent quality and stability in dimensionality as well as a flawless surface. The precision of the dies allow for the development of parts with intricate geometries that are usually impossible through other manufacturing methods.

One of the main advantages of diecasting is the efficiency in mass production. When the dies are made, they can be used for the production of thousands of identical parts that are identical with little variation. This level of consistency is vital for companies that need large quantities of consistent components. In addition, diecasting is renowned as a material that is efficient. It produces little scrap, because any excess metal can be recycled and reused in subsequent casting cycles. This reduces not just costs for materials, but it also encourages sustainable manufacturing practices by minimizing waste and conserving resources. A combination of efficiency, high speed, and material efficiency makes diecasting an attractive choice for manufacturers aiming to optimize their processes for production.

Diecasting is widely used across various industries due to its versatility as well as the variety of different materials utilized. For the automotive sector diecast parts are vital for producing components such as engine blocks, transmission cases as well as structural components. Aerospace relies on diecasting for lightweight robust parts with high strength that can stand up to the rigorous conditions of flight. In the field of consumer electronics, diecast parts are utilized for housings and frames, providing quality and durability in electronics. The versatility of diecasting also can be applied to communications, medical, and power tool industries and demonstrates its vast use and significance. To receive extra information please check out Senadiecasting

Diecasting's versatility extends beyond its mechanical benefits to its adaptability in various areas. For electronics, diecasting is used to create enclosures, connectors and heat sinks to ensure that the devices are safe and operate efficiently. Diecasting is widely used to create everyday items, including the kitchen appliance to power tools, where accuracy and longevity are essential. Its ability to make intricate and intricate components can make diecasting a desirable option for engineers and designers looking to create new ideas and increase product functionality. In allowing a variety of metals as well as allowing the integration of sophisticated features it allows for the development of innovative products in a variety of fields.

Diecasting is a crucial manufacturing process that allows for the manufacturing of precision quality metal components across a wide range of industries. Its capacity to design complicated shapes, with precise tolerances and flawless finishes is essential for projects with intricate specifications and consistent high-quality. Cost-efficiency and efficiency of diecasting add to its value, supporting mass production while maintaining high standards. As the technology evolves and the need for reliable sturdy, light, and lightweight components expands, diecasting will continue to be a key component of modern manufacturing. It drives improvement and quality in production.